Introduction

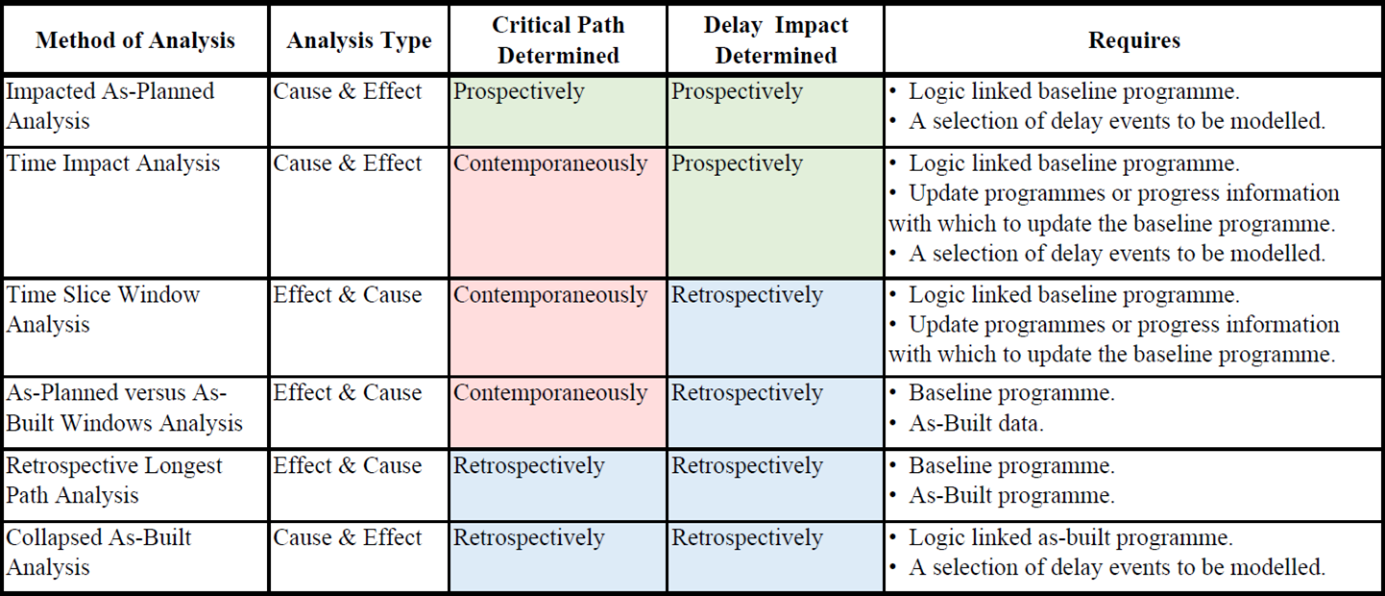

Some delay analysts favour some methods of analysis over others. However, the decision as to which method of analysis to use is generally driven by several factors such as; the type of contract, the type of project/build, the availability of suitable programmes, the amount and quality of records, regular and auditable progress records, nature of the claim, and the time available to complete the analysis.

The method used, and the final result, is often a compromise based on the information available and the cost of the analysis. It is important to understand the advantages and limitations of each method, and to keep those in mind when carrying out the analysis and in its presentation.

Delay Analysis Methods

There is much written about the various methods of Delay Analysis that can be used. The Society of Construction Law Delay and Disruption Protocol sets out the most widely used methods of assessing delay, these are the methods that are considered in this Article:

Each method relies on particular information being available. It is the information that is available which will dictate which technique to use in most cases. The more robust methods of analysis can only be carried out if specific information and records have been prepared in the right way during the project.

The nature and quality of the records available is the single most important factor affecting the decision as to what technique to adopt. For further information on each method of analysis, the reader is encouraged to read the SCL Delay and Disruption Protocol.

Impacted As-Planned Analysis

In this method, events or delays are added into an "as-planned" programme. The "as-planned" programme used in most cases would be the project Contract programme, which is the programme that is most likely in use at the very start of the project.

The individual delays must be identified and the dates that the delays started and finished established and inserted into the "as-planned" programme as "sub-networks". These are then linked to the activities that are relevant to the event in question. The difference between the planned project completion date in the baseline programme and the impacted completion date quantifies the delay.

The benefit of this method is that it is the simplest and quickest, therefore, likely the cheapest method of analysis to carry out.

However, there are a number of negatives to this method. Practically there can sometimes be difficulties finding the right or most appropriate programme to use, and the programme needs to have been prepared with sufficient/robust logic links between the different activities to enable the delay events to be added and the impact properly calculated.

Fundamentally, the method does not take account of the actual progress of the works, so the analysis could be deemed to be entirely theoretical with the critical path and impact being determined prospectively. Therefore, this method is best suited for delay events that have occurred at the very start of a project and would generally be considered the least favoured method of analysis.

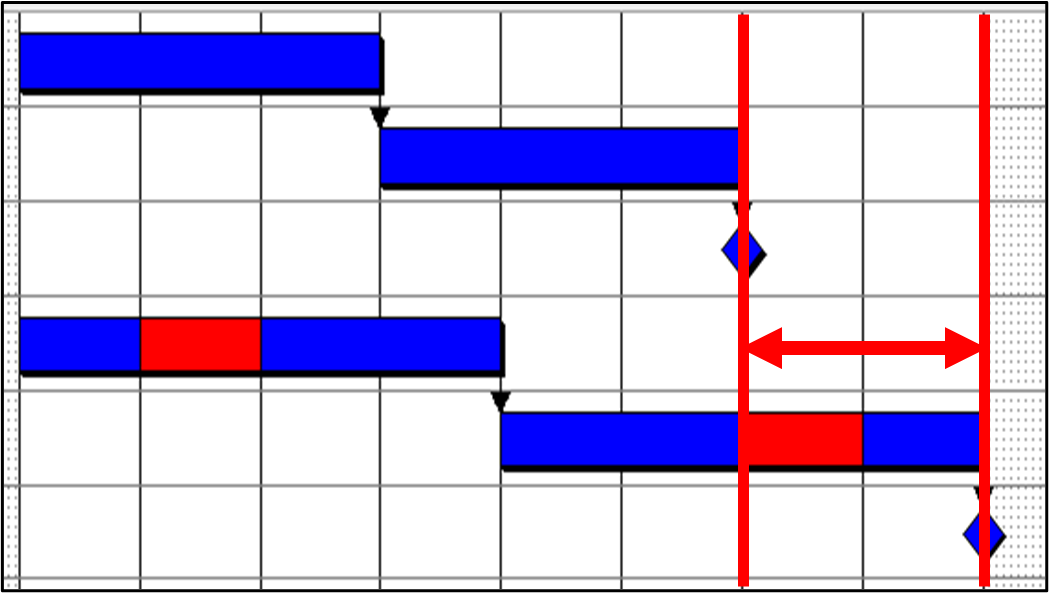

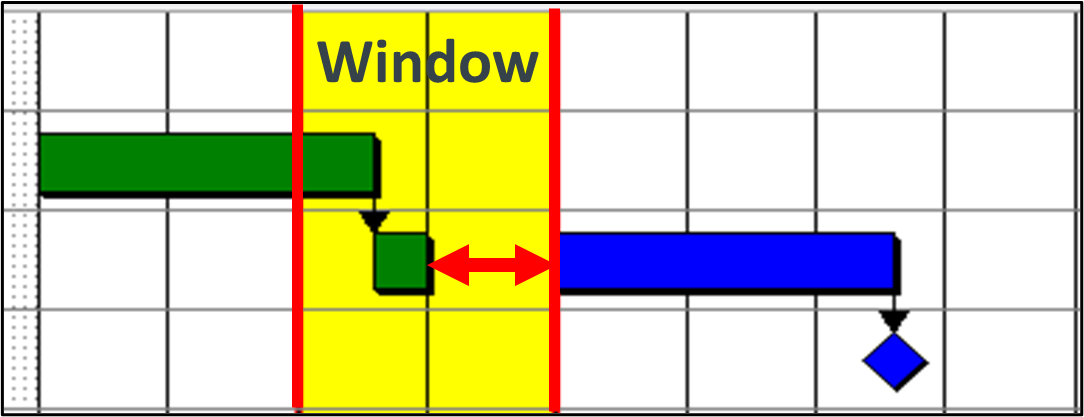

Time Impact Analysis

This uses the same approach as the Impacted As-Planned method with delays being inserted into the "as-planned" programme as "sub-networks". However, rather than using a programme from the start of the project, this method employs a programme that has been updated shortly before the delay events occurred making the assessment more contemporaneous.

The up-to-date programme could be the baseline programme that has been updated with progress, or it could be a new or revised programme that was prepared part way through the works.

This method is commonly used, as it mirrors the process in which programmes are typically managed and maintained on construction projects, therefore it reflects the "thinking" of the project team at the time the delay events were occurring. It is useful to use when a project is ongoing for timely resolution of delays, with this method being typical of a programme managed under an NEC form of contract.

The method is relatively quick to implement providing that an updated programme has been maintained on the project and it does not require a detailed as-built programme. However, the more delay events that need to be modelled, the more time consuming and complex the analysis will become.

As with an Impacted As-Planned Analysis, a Time Impact Analysis could also be deemed to be theoretical, as again the critical path and impact is determined prospectively.

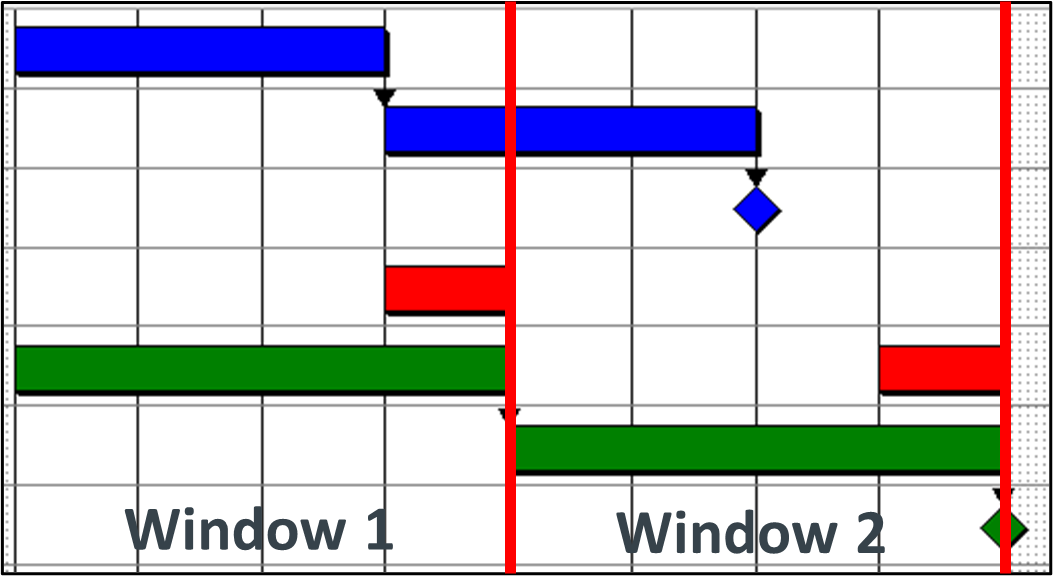

Time Slice Window Analysis

The "Time Slice Windows" and "Time Impact" analysis methods both use “up-to-date” (at the point the delay event impacts) programmes. In the "Time Slice Window Analysis" the programmes are used to slice the time into “windows”, typically monthly. An up-to-date programme marks the start of the window, and another up-to-date programme marks the end of the window.

The analysis programmes at the start and end of each window are compared to assess how much delay occurred in each window and to identify which activities were delayed. The causes of delay are then examined in further detail.

The benefit of this method is the critical path is determined contemporaneously, as the works progressed, so it accounts for potential changes in the critical path which can occur on complex projects or projects with many sections.

This method requires up-to-date programmes that would typically be prepared each month and they must contain accurate logic links. It is more time consuming than the first two methods described above as the analyst needs to delve more into the detail of the project records to try to determine exactly what happened in each window and establish the causes of any potential delays as such.

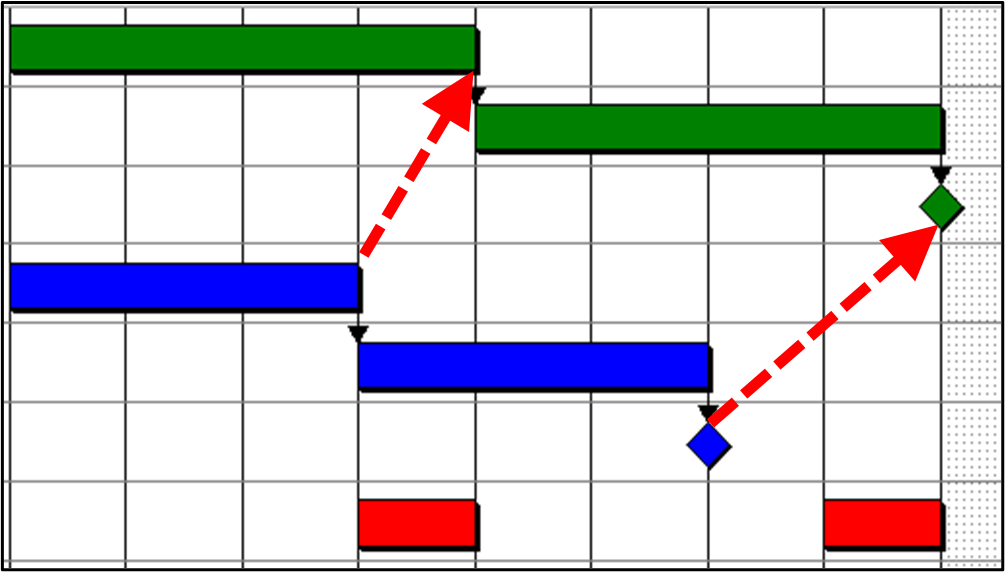

As-Planned versus As-Built Window Analysis

This method again breaks the analysis into windows. However, rather than being split into time-slices that are dictated by the data date of updated programmes, each window is book ended by key events, milestones or activities.

The as-built dates are ascertained typically by an in-depth review of contemporaneous records like progress reports, site diaries, progress photographs, along with interviewing site staff. A comparison is then made between the planned start and finish dates with the actual start and finish dates to see where the critical delays have occurred and to assess the extent of those delays.

A windows analysis is usually easy to calculate and understand. It can identify delays as well as acceleration or mitigation quantities and considers the actual conditions and construction progress.

Further investigation is then often required to demonstrate the causes of delay. However, there may be a degree of subjectivity to determine criticality. Therefore, it is best used on more simple projects with few potential competing critical paths of work, with accuracy being diminished if the critical path deviates from the planned programme.

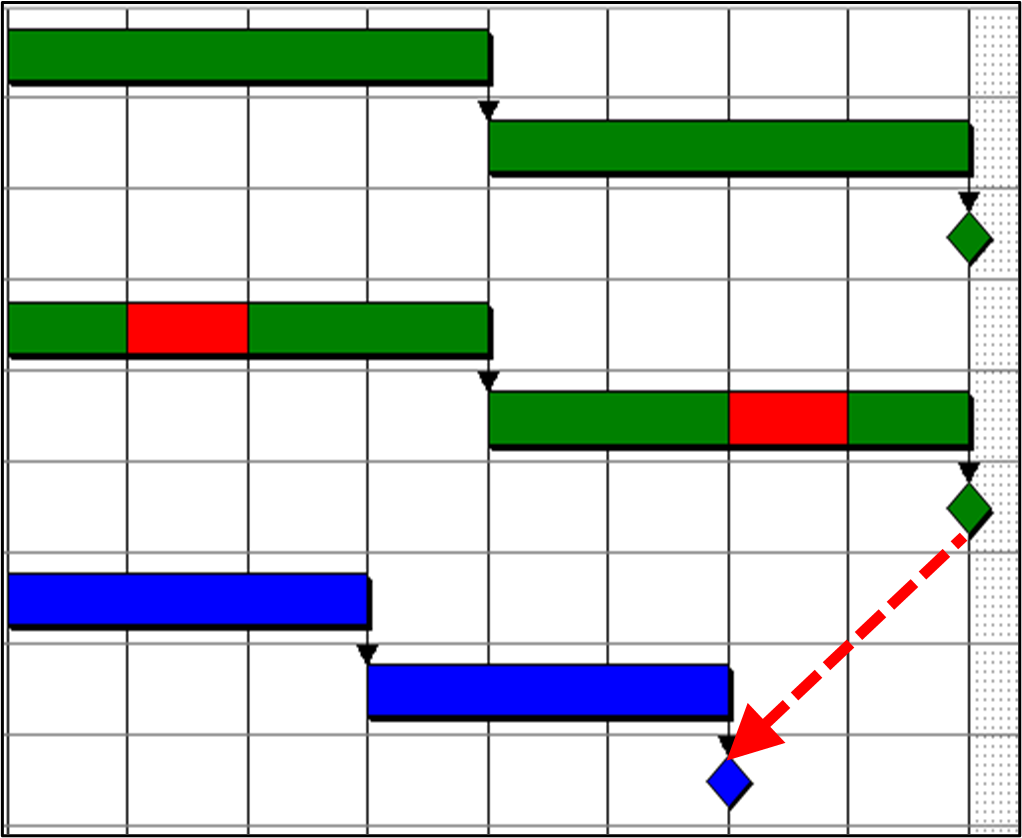

Retrospective Longest Path Analysis

This method is typically utilised when a project has been completed using a detailed as-built programme to identify the as-built critical path from the start of the project through to the end.

In a similar way to the As-Planned versus As-Built Window Analysis, the dates of the critical as-built activities are then compared against the dates on the baseline programme to see how late they were and thus how much delay has occurred. The causes of delay are then identified.

This method requires a detailed as-built programme or the information needed to produce one. It also requires a baseline programme. Producing an as-built programme from scratch can be very time consuming unless one has been developed and maintained during the course of the works.

It is important to understand that the critical path identified as the ‘longest’ path through a programme will potentially be different to a "forecasted" critical path identified by an "Impacted As-Planned" or "Time Impact" method of analysis, and will also potentially be different to a "contemporaneous" critical path that is identified using one of the "Window" analysis methods. In addition, this method will not identify potential changes in the critical path unlike a contemporaneous type of analysis.

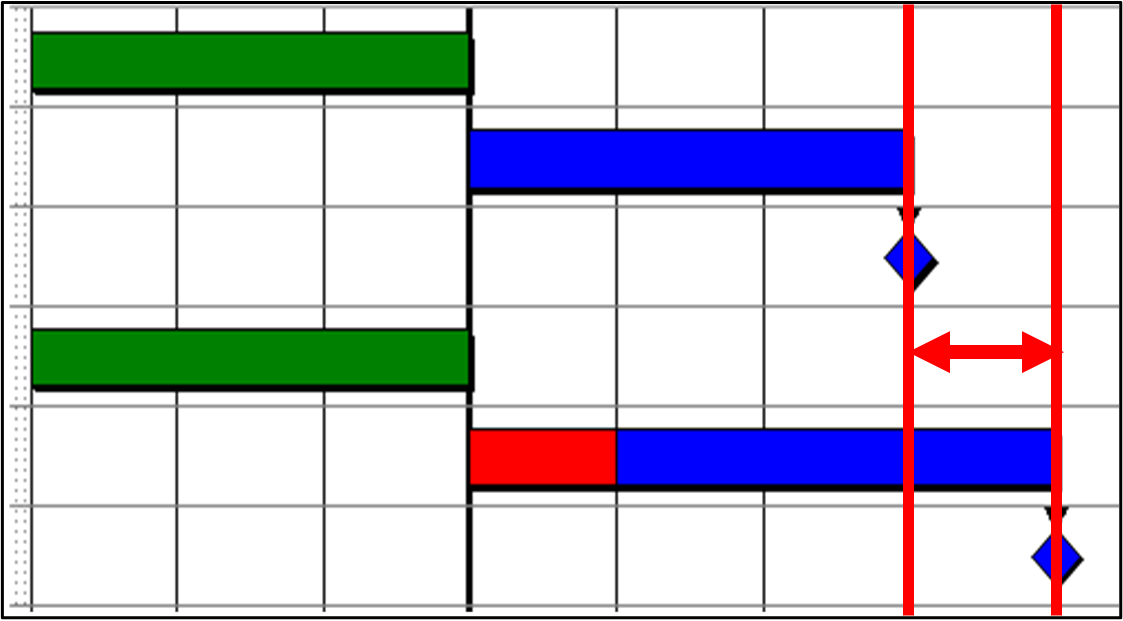

Collapsed As-Built Analysis

This method requires a detailed and robustly logic linked as-built programme, or detailed records to enable one to be created, however does not necessarily require an as-planned/baseline programme for comparison.

In this method delaying events are removed from the as-built programme to assess what would have happened if the delay events had not occurred. This method is often referred to as “but for” as the analysis establishes when the works would have been completed “but for” the delays identified.

This methodology is easy to understand and, along with the benefit not requiring a baseline, it also does not necessarily require contemporaneous programme updates. However, the analysis can be manipulated with the insertion of after-the-fact logic links and delay events.

Conclusions

Delay Analysts must be aware of the pro’s and con’s of each analysis method to determine which one is most suitable for the case at hand.

It is important to understand that use of different methods of delay analysis can result in a different assessment of what may be deemed to be the project critical path. This is particularly evident when comparing a prospective approach to a retrospective approach (e.g. Time Slice Windows v Longest Path).

The more robust methods of analysis can only be carried out if specific information and records have been prepared in the right way during the project. The choice of delay analysis depends on the information available. The nature and quality of the records available is the single most important factor affecting the decision as to what technique to adopt.

-

Sheffield

The Annexe,

260 Ecclesall Road South,

Ecclesall,

Sheffield,

S11 9PSTel - 0114 230 1329

-

London

Adam House,

7-10 Adam Street,

London,

WC2N 6AATel – 020 7520 9295

-

Leeds

Suite 69,

4100 Park Approach,

Thorpe Park,

Leeds,

LS15 8GBTel - 0113 397 0358

-

Warrington

Suite 41,

Lakeview 600,

Lakeside Drive,

Centre Park Square,

Warrington,

WA1 1RWTel - 01925 984705

-

Manchester

3 Hardman Street,

Manchester,

M3 3HFTel - 0114 230 1329

-

Birmingham

Birmingham Business Park,

4200 Waterside Centre,

Solihull Parkway,

Birmingham,

B37 7YNTel - 0121 481 2381

-

Liverpool

Horton House,

Exchange Flags,

Liverpool,

L2 3PFTel - 07753 837149