Introduction

-

If you are unfortunate enough to find yourself having to prepare a retrospective delay analysis you will find that one of the most important decisions to be made is which delay analysis technique should we use?

-

There are a number of factors which will drive this decision; the availability of suitable programmes, the amount and quality of records, regular and auditable progress records and the nature of the claim itself (for example, numerous small delays, a single or a few major delays or disruption).

-

Ramskill Martin have, on several occasions, encountered poor decision making with regards to the techniques adopted.

-

On a number of occasions Ramskill Martin have encountered situations where the delay analysis technique has not been considered in terms of its suitability and practicality. On each occasion the claim failed because it either did not stand up to factual scrutiny or because the analysis did not attempt to address the inherent problems with the technique adopted. When adopting a technique, you must demonstrate that any deficiencies have been considered (and they all have them) and accounted for in any conclusion presented.

Choosing a Delay Analysis Technique

-

One of the purposes of a delay analysis is to establish the causes of delay and ascertain their effect on the completion date. The Society of Construction Law Delay and Disruption Protocol sets out the most widely used methods of assessing delay:

-

Impacted As-Planned.

-

Time Impact.

-

Time Slice Windows.

-

As-Planned v As-Built Window.

-

Longest Path.

-

Collapsed As-Built.

-

-

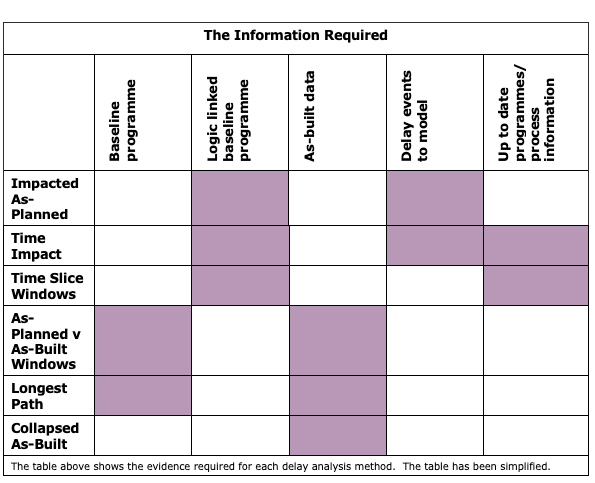

Each method relies on particular information being available. It is the information that is available which will dictate which technique to use in the vast majority of cases.

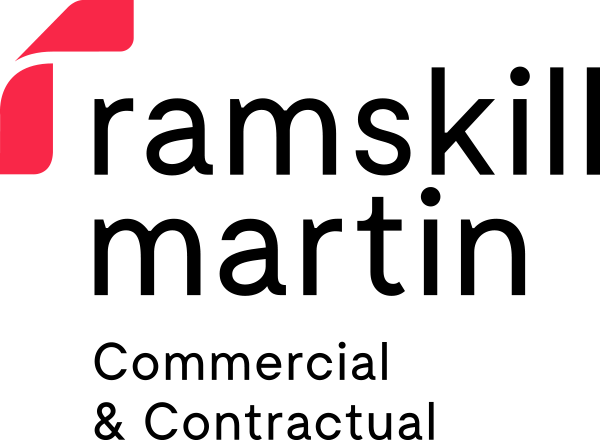

Impacted As-Planned Analysis

-

In this method delays are added on to the as-planned programme, which is a programme from near the start of the project, and the effect of the delays are assessed.

-

The individual delays must be identified and the dates that the delays started and finished established. This typically involves interviewing site staff and trawling site records to piece together the delays. The extent of this exercise depends on how many delays are selected and how complex the events are. This interview and trawling exercise can be both lengthy and costly.

-

Once the delays have been identified they are impacted onto the as-planned programme. Practically there can be difficulties finding the right programme. The programme needs to have been prepared with sufficient logic links between the different activities to enable the delay events to be added and the effect properly calculated.

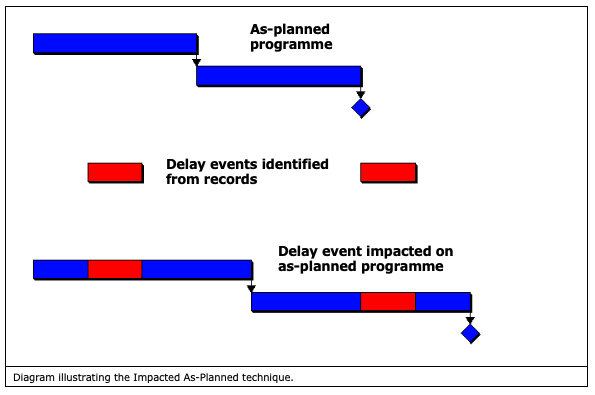

Time Impact Analysis

-

This uses the same approach as the Impacted As-Planned method with delays being impacted on an as-planned programme. However, rather than using a programme from the start of the project, this method employs a programme that was up-to-date shortly before the delay events occurred making the assessment more contemporaneous.

-

The up-to-date programme could be the baseline programme that has been updated with progress, or it could be a new or revised programme that was prepared part way through the works.

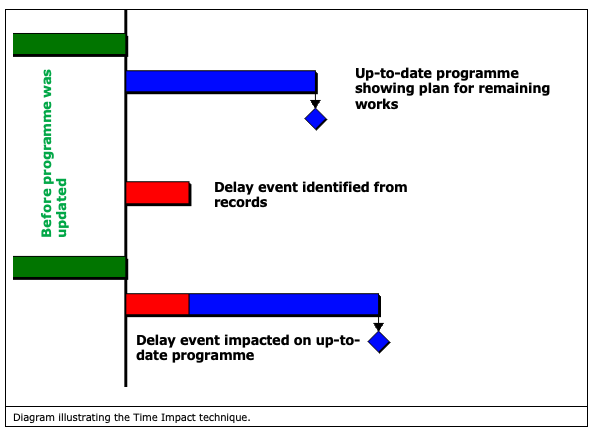

Time Slice Windows Analysis

-

The Time Slice Windows and Time Impact methods both use “up-to-date” (at the point the delay event impacts) programmes. In the Time Slice Windows method the programmes are used to slice the time into “windows”. An up-to-date programme marks the start of the window and another up-to-date programme marks the end of the window.

-

The analysis programmes at the start and end of each window are compared to assess how much delay occurred and to identify which activities were delayed. The causes of delay are then examined in further detail.

-

This method requires up-to-date programmes that would typically be prepared each month and they must contain accurate logic links.

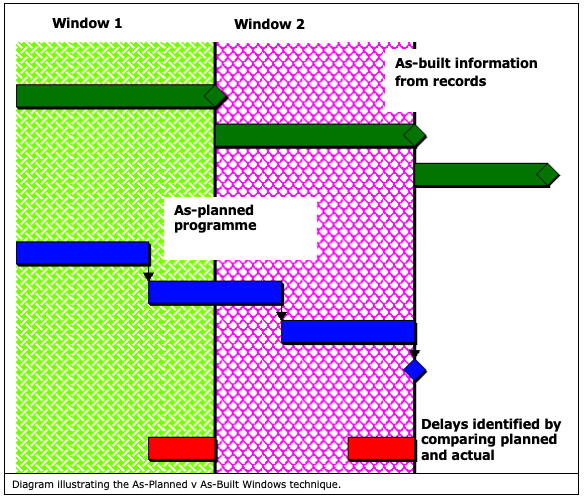

As-Planned -v- As-Built Windows Analysis

-

In this method as-built dates are ascertained typically by interviewing site staff, reviewing progress reports, site diaries, progress photographs and other records. The as-built dates are then compared with the baseline programme to see where the critical delays have occurred and to assess the extent of those delays.

-

Further investigation is then often required to demonstrate the causes of delay.

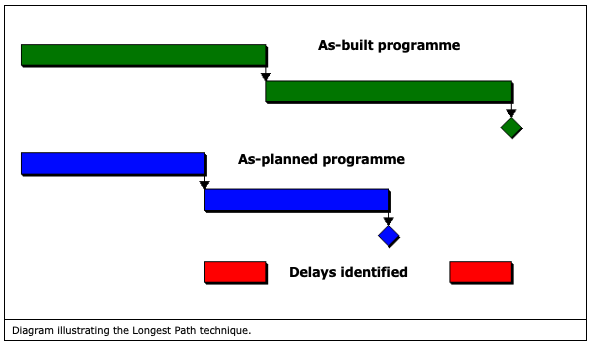

Longest Path Analysis

-

A detailed as-built programme is used to identify the as-built critical path. The dates of the critical activities are then compared against the dates on the baseline programme to see how late they were and thus how much delay has occurred. The causes of delay are then identified.

-

This method requires a detailed as-built programme or the information needed to produce one. It also requires a baseline programme.

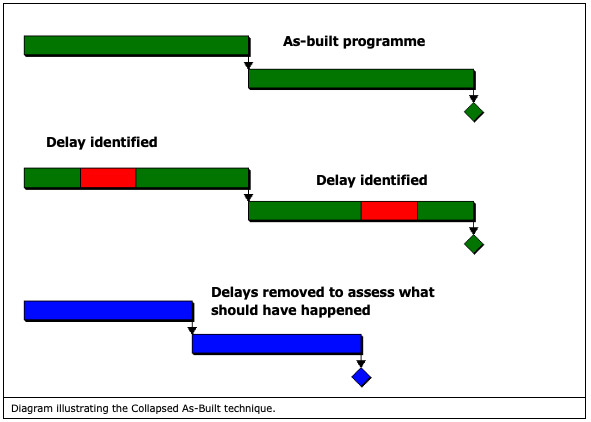

Collapsed As-Built Analysis

-

In this method delaying events are removed from the as-built programme to assess what would have happened if the delay events had not occurred. This method is often referred to as “But For” as the analysis establishes when the works would have been completed “but for” the delays identified.

-

This method requires a detailed and logic linked as-built programme or detailed records to enable one to be created.

Conclusions

-

The more robust methods of analysis can only be carried out if specific information and records have been prepared in the right way during the project. The choice of delay analysis depends on the information available. Each method requires specific information which is illustrated in a simplified way in the table below. The nature and quality of the records available is the single most important factor affecting the decision as to what technique to adopt.

-

Ramskill Martin has issued an article on the importance of record keeping and the best form these records should take:

Click here for Programmes: Progress Monitoring and Reporting

-

Where a delay has occurred, and there is a dispute, it might be possible to carry out a “quick as-built” assessment to identify the likely causes of delay and their effect. This can be used to help make a commercial decision on how to progress a claim. Ramskill Martin’s CFDA service can also assist in making this key decision.

ARTICLE BY: DAVID TATHAM (BSc (Hons), MSc, LLB, MCIArb, ICIOB)

(david.tatham@ramskillmartin.co.uk)

-

Sheffield

The Annexe,

260 Ecclesall Road South,

Ecclesall,

Sheffield,

S11 9PSTel - 0114 230 1329

-

London

Adam House,

7-10 Adam Street,

London,

WC2N 6AATel – 020 7520 9295

-

Leeds

Suite 69,

4100 Park Approach,

Thorpe Park,

Leeds,

LS15 8GBTel - 0113 397 0358

-

Warrington

Suite 41,

Lakeview 600,

Lakeside Drive,

Centre Park Square,

Warrington,

WA1 1RWTel - 01925 984705

-

Manchester

3 Hardman Street,

Manchester,

M3 3HFTel - 0114 230 1329

-

Birmingham

Birmingham Business Park,

4200 Waterside Centre,

Solihull Parkway,

Birmingham,

B37 7YNTel - 0121 481 2381

-

Liverpool

Horton House,

Exchange Flags,

Liverpool,

L2 3PFTel - 07753 837149